DSW Industry manufactures precision-engineered Dewar Cylinders and insulated cryogenic cylinders designed to maintain extremely low temperatures for gases such as liquid nitrogen (LN2), liquid oxygen (LOX), argon (LAr), and carbon dioxide (CO₂). These welded insulated cryogenic cylinders are ideal for laboratory, medical, industrial, and research applications, providing safe, reliable, and long-lasting cryogenic storage.

With advanced vacuum insulation and rigorous production standards, DSW Industry Dewar Cylinders reduce boil-off, maintain gas purity, and ensure operational safety for your most critical applications.

Key Features

Advanced Vacuum Insulation

- High-quality vacuum-insulated vessel design to minimise heat transfer

- Outstanding thermal retention for prolonged cryogenic liquid storage

- Reduces liquid boil-off and enhances overall efficiency

Safe and Durable Construction

- Manufactured to stringent safety standards for cryogenic equipment

- Robust steel and aluminium construction for lasting performance

- Designed for use in both indoor and outdoor environments

Wide Range of Cryogenic Gases

- Suitable for liquid nitrogen cylinders (LN2)

- Available for oxygen dewar cylinders (LOX)

- Configurable for argon dewar cylinders (LAr)

- Custom sizes available upon request

Portable and Easy to Handle

- Offered in portable dewar cylinder formats

- Ergonomically designed for convenient transport

- Ideal for laboratories, hospitals, and industrial facilities

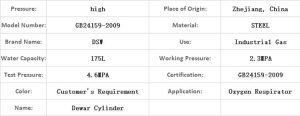

Dewar Size Chart

‘

‘

Applications

- Laboratories & Research – Safe LN2 storage for experiments and sample preservation

- Medical & Healthcare – Cryogenic cooling and storage of medical gases

- Industrial Gas Supply – Bulk and portable storage solutions for oxygen, nitrogen, and argon

- Cryogenic Processing & Manufacturing – Reliable, low-loss liquid gas storage

Inspection Guarantee

Our Dewar Cylinders are subjected to rigorous testing and inspection:

- Welding Seams – 100% RT & PT non-destructive testing

- Strength Testing – High-purity nitrogen up to 99.999%

- Leak Detection – Advanced helium mass spectrometer testing

- Inner Container Cleanliness – Passivation, pickling, UV inspection

- Assembly – Inner & outer containers assembled within 2.5 hours

- Interlayer Insulation – Special treated high-quality perlite

- Final Protection – Nitrogen filling at 0.2MPa to protect tanks

Reviews

There are no reviews yet.