Industrial Ambient Air Vaporizers For Filling Station

DSW industry provides high-performance ambient vaporizer replacements for other cryogenic, CO2 beverage manufacturers, LN2 dosing, water treatment, and LNG equipment.

Since 2002, DSW international has provided high-quality parts with customer & technical services support – so you get the right replacement parts at the right time to keep your equipment operating at peak efficiency.

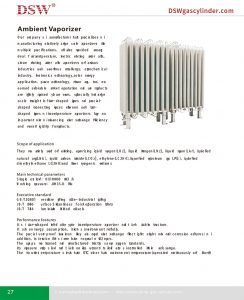

Air ambient vaporizers are used to vaporize liquefied gases such as nitrogen, oxygen, and argon by using the surrounding air. They are cost-effective and reliable, with maximum vaporization capacity at minimal or no operation cost.

Technical Data Of Ambient Air Vaporizer

| Item Number | Working Medium | Design Pressure ( Mpa) | Working Pressure (Mpa) | Design Temperature | Heat Exchange Area |

| AV50/3.0 | Liquid Oxygen, Liquid Argon, Liquid Nitrogen | 3.3 | 3.0 | -196 to 50 degree | 12.5m2 |

DSW™ ambient air vaporizers have become the industry standard, and Supergap vaporizers use natural convection of air to vaporize liquefied gases.

These air vaporizers are designed to match your flow requirement to avoid low-temperature gas entering the product pipeline.

DSW’s Ambient air Vaporizers (VAP) are made of aluminum cooling fins for heat exchange and can be connected to increase vaporizing capacity.

For more flexibility, VAP units can be interconnected with standard (universal) inputs & outputs (flanges). Continuous flow is guaranteed 24 hours a day using several units geared with a manual or automatic switching system (valves).

High Performance

With its cooling fins patented system, DSW’s VAP offer a maximum Heat exchange surface.

Versatility

DSW’s modular design enables modification of the overall flow capacity (between 70m³/h to 1500Nm³/h at 20°C). Vaporization in simple or dual phase (liquid + gas)