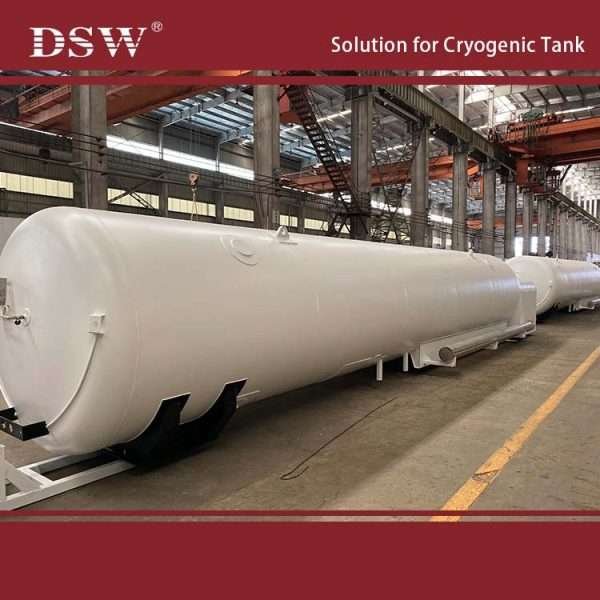

LO2, LN2, LAR Cryogenic Tank

Cryogenic tanks, also known as cryo tanks or cryogenic storage tanks, are specialized containers designed to store cryogenic substances, such as liquid nitrogen, liquid oxygen, or liquefied natural gas (LNG).

These cryo tanks possess several distinct features that enable the safe and efficient handling of cryogenic materials.

DSW offers a wide range of cryogenic tanks, such as liquid oxygen tanks, liquid nitrogen tanks, liquid argon tanks, and liquid Nitrous Oxide tanks.

Features

Insulation: Heavy insulation minimizes heat transfer into the tank and maintains low temperatures. They are typically constructed with multiple layers of insulation materials.

Pressure options: 8bar, 16bar, or as per user specifications.

Safety Features: These features may include pressure relief valves, rupture discs, and pressure monitoring systems to prevent over-pressurization.

International standards encompass GB (National Standards of the People’s Republic of China), ASME (American Society of Mechanical Engineers), and CE (Conformité Européenne).

Vapor Space: Vapor space management is crucial to prevent the accumulation of excessive pressure or the release of hazardous gases. Cryotanks may include systems for controlling and managing the vapor space, such as pressure regulation systems or venting mechanisms.

Transfer Connections: These connections may include fill/drain valves, pressure relief connections, and vapour return lines. They are designed to facilitate the controlled transfer of the cryogenic material into and out of the tank while minimizing the risk of leaks or accidents.

We use a new material, strong stainless steel, to reduce the tank’s self-weight and increase efficiency.

Also, we provide non-standard size design services for clients.

Our tanks are widely used in gas, chemical, machinery, metallurgy, medicine, nuclear power, and other industries.

Design and Specifications of LO₂, LN₂, LAR Cryo Tank

| Parameter | Inner Tank | Outer Tank |

| Design Pressure | 0.84/1.68 MPa | -0.1 MPa |

| Working Pressure | 0.8/1.6 MPa | 3 Pa |

| Temperature (℃) | -196 | 50 |

| Loading Medium | LO2, LN2, LAR | – |

| Material | 06Cr19Ni10 | Q235-B |

| Test Pressure (MPa) | 1.1/2.0 | -0.1 |

| Interlayer | Brilliant Expansion Perlite | – |

| Leak Test | Helium Test | – |

LO₂, LN₂, LAR Cryogenic Tank

(Vacuum Powder Heat Insulation) – Main Specifications

| Type | Model | Working Volume (M3) | Working Pressure (MPa) | Evaporation per day (%/d) | Weight (Kg) | Working Pressure (MPa) Diameter x Length x Thickness |

|||||||

| LO2 | LN2 | LAr | Inner tank | Total weight | |||||||||

| Horizontal type |

DSWH-5/0.8 | 5 | 0.8 | 0.43 | 0.65 | 0.4 | 1000 | 4490 | Inner Tank: 1400×3680×6 Outer Tank: 1900×4980×8 |

||||

| DSWH-5/16 | 5 | 1.6 | 0.43 | 0.65 | 0.4 | 1550 | 5100 | In ner Tank:1400×3680×10 Outer Tank: 1900×4980×8 |

|||||

| DSWH-10/0.8 | 10 | 0.8 | 0.36 | 0.55 | 0.38 | 1920 | 7510 | Inner Outer |

Tank: Tank |

1700×4950× 2200×6250×8 |

|||

| DSWH-10/1.6 | 10 | 1.6 | 0.36 | 0.55 | 0.38 | 3040 | 8550 | Inner Tank Outer Tank |

1700×4950×1 2200×6250×8 |

||||

| DSWH-15/0.8 | 15 | 0.8 | 0.35 | 0.53 | 0.3 | 2650 | 9450 | Inner Tank: 1900×5950×8 Outer Tank 2400×7150×8 |

|||||

| DSWH-15/1.6 | 15 | 1.6 | 0.35 | 0.53 | 0.37 | 4380 | 11250 | In ner Tank: 1900×5950×14 Outer Tank 2400×7150×8 |

|||||

| DSWH-20/0.8 | 20 | 0.8 | 0.33 | 0.5 | 0.35 | 3350 | 11350 | Toner Tank Outer Tank |

2100×6465×8/14 2600×7830×8 |

||||

| DSWH-20/1.6 | 20 | 1.6 | 0.33 | 0.5 | 0.35 | 4950 | 13400 | In ner Tank:2100×6465×14 Outer Tank 2600×7830×8 |

|||||

| DSWH-30/0.8 | 30 | 0.8 | 0.29 | 0.44 | 0.31 | 5210 | 17400 | Inner Tank: 2400×7410×10 Outer Tank: 3000×8750×10 |

|||||

| DSWH-30/1.6 | 30 | 1.6 | 0.29 | 0.44 | 0.3 | 8180 | 20400 | Inner Outer |

Tank Tank |

2400×7410×16 3000×8750×10 |

|||

| DSWH-50/0.8 | 50 | 0.8 | 0.23 | 0.35 | 0.24 | 8000 | 26150 | Inner Tank: Outer Tank |

2600×10380×10 3200×11780×12 |

||||

| DSWH-50/1.6 | 50 | 1.6 | 0.23 | 0.35 | 0.24 | 13535 | 31750 | Inner Outer |

Tant Tank |

2600×10380×18 3200×11750×12 |

|||

| DSWH-100/0.8 | 100 | 0.8 | 0.16 | 0.25 | 0.17 | 14740 | 45900 | Inner Tank: Outer Tank |

3000×15425×12/14 3500×16870×14 |

||||

| DSWH-100/1.6 | 100 | 1.6 | 0.16 | 0.25 | 0.17 | 27070 | 5822 | Inner Tank: 3000×15425×22 Outer Tank 3600×16870×14 |

|||||

DSW storage tanks are designed, manufactured, and tested as per ASTM standards, ISO, safety technology supervision regulations for pressure vessels, and some other reference Chinese standards.

DSW warranty is one year after shipment. Within one year, we will send broken spare parts at our expense.

Upon request, if it is proven to be our product defect,

In fact, we rarely receive any requests for spare parts.

If the cryogenic tanks are correctly maintained, they shall last 15 to 20 years.