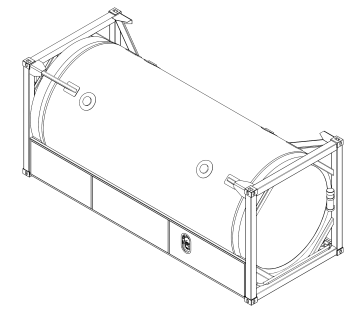

What is a cryogenic tank?

Cryogenic tanks are liquid tanks, tank containers, or cryogenic vessels with double-wall construction made of a stainless steel inner vessel and carbon steel outer vacuum jacket with MLI standard. Other options are single-wall vessels, insulated on non-insulated or triple-wall containers that store high-temperature gases like LNG, co2, and nitrous oxide. These are gas supply system parts used in various sectors, such as steel processing, medical technology, electronics, water treatment, energy production, and food handling.

What are cryogenic tanks made of?

A cryogenic tank is composed of a structure divided into two fundamental parts: An inner vessel made of stainless steel and designed to withstand very low temperatures. An outer container made of carbon steel.

1. Construction of Cryogenic Tanks

Cryogenic tanks typically feature a double-wall construction:

- Inner Vessel: Made of stainless steel (commonly 304L or 316L) to withstand extremely low temperatures and resist corrosion.

- Outer Vessel: Made of carbon steel or stainless steel, providing structural support and maintaining the vacuum insulation.

Alternative designs include single-wall tanks with external insulation, or triple-wall tanks for high-performance applications such as LNG, CO₂, and nitrous oxide storage.

1.1 Insulation System

Between the inner and outer vessels, a vacuum-insulated layer is maintained, often with multi-layer insulation (MLI) or other high-performance insulating materials. This combination:

- Minimises heat transfer

- Reduces boil-off of cryogenic liquids

- Ensures safe long-term storage

1.2 Welding and Assembly

Precision welding of the outer shell ensures structural integrity and maintains vacuum insulation. The inner pressure vessel is carefully constructed to withstand cryogenic temperatures without compromising strength.

2. Materials Used in Cryogenic Tanks

| Component | Material | Function |

|---|---|---|

| Inner vessel | Stainless steel (304L, 316L) | Withstand ultra-low temperatures, corrosion resistance |

| Outer vessel | Carbon steel or stainless steel | Structural support, insulation housing |

| Insulation | Multi-layer insulation (MLI), vacuum | Reduce heat transfer and boil-off |

| Piping & valves | Stainless steel, alloy steels | Safe handling and delivery of cryogenic fluids |

What is the pressure in a cryogenic tank?

The maximum working pressure of cryogenic storage tanks ranges from 2 to 37 bar, depending on where the tank will be used. It can be designed vertically or horizontally according to customer demand.

Cryogenic tanks are designed to handle a wide range of pressures depending on the application:

| Tank Type | Maximum Working Pressure | Orientation |

|---|---|---|

| Standard industrial tanks | 2–37 bar | Vertical or horizontal per customer requirement |

| Medical oxygen tanks | 18 bar | Vertical/horizontal |

| LNG storage tanks | 22–36 bar | Horizontal or vertical |

Safety devices such as pressure relief valves and burst discs are essential to prevent overpressure.

What is the capacity of a cryogenic tank?

The tanks range in capacity from 3,000 to > 100,000 liters and have standardized working pressures of 18, 22, or 36 bar, respectively.

Which is used as a cryogenic liquid?

Liquefied gases, such as liquid nitrogen and helium, are used in many cryogenic applications. Liquid nitrogen is the most commonly used element in cryogenics and is legally purchasable around the world. Liquid helium is also widely used and allows for reaching the lowest attainable temperatures.

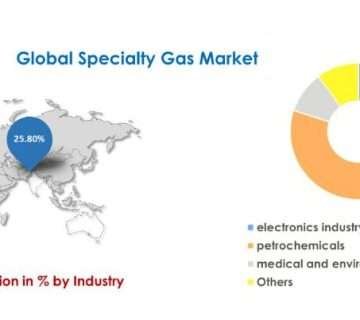

Melted gases are used in various industries: metal processing, modern clinical technology, electronics, water therapy, energy manufacturing, and food handling. Consumers are significantly receiving these industrial gases in fluid form at cryogenic temperature levels, permitting them to be stored on-site for future use.

Cryogenic fluids

Cryogenic fluids with their boiling point in kelvins and degree Celsius.

| Fluid | Boiling Point (K) | Boiling Point (°C) | Common Applications |

|---|---|---|---|

| Helium-3 | 3.19 | -269.96 | Low-temperature physics |

| Helium-4 | 4.214 | -268.94 | Superconducting magnets, MRI |

| Hydrogen | 20.27 | -252.88 | Fuel, chemical industry |

| Neon | 27.09 | -246.06 | Electronics, lasers |

| Nitrogen | 77.09 | -196.06 | Medical, food preservation, industrial cooling |

| Air | 78.8 | -194.35 | Industrial applications |

| Fluorine | 85.24 | -187.91 | Chemical synthesis |

| Argon | 87.24 | -185.91 | Welding, electronics |

| Oxygen | 90.18 | -182.97 | Medical, steelmaking |

| Methane | 111.7 | -161.45 | LNG, fuel applications |

6. Applications

- Medical: Liquid oxygen for hospitals and emergency supply.

- Industrial & Energy: LNG storage, gas supply for chemical and petrochemical plants.

- Metal Processing: Cryogenic treatment of tool steels to improve hardness and durability.

- Electronics & Research: Superconducting magnets, semiconductor cooling.

- Food & Water Treatment: Nitrogen for freezing and preservation, oxygen for water treatment.

7. Safety Considerations

Cryogenic liquids are extremely cold and pose hazards such as frostbite, overpressure, and asphyxiation. Proper handling, inspection, and maintenance are essential:

- Regular vacuum integrity checks

- Inspection of insulation and welds

- Pressure relief valve testing

- Compliance with ASME, EN, and local regulations

No comment