Effective Heat and Pressure Management to Prevent Boil-Off Gas in Cryogenic Storage

In the cryogenic industry, managing heat and pressure within storage tanks is a critical aspect of ensuring gas remains in its liquid state. If temperatures rise too much, Boil-Off Gas (BOG) occurs, resulting in product loss and operational inefficiencies. Since BOG is challenging to control once it starts, it is crucial to implement proactive measures to prevent it. This article explores how heat and pressure interact within cryogenic systems and presents insulation solutions that minimize BOG risks.

The Critical Relationship Between Heat and Pressure

Heat and pressure are intrinsically linked in cryogenic storage. An increase in temperature leads to a rise in pressure, which can exacerbate BOG issues. Several factors contribute to temperature increases, including:

- Heat Absorption from Ambient Air: Storage tanks and lines can absorb heat from the surrounding environment.

- Heat Generated by Equipment: The operation of pumps and other machinery can introduce additional heat.

- Vapor Displacement: Liquid entering the tank can displace vapor, leading to temperature variations.

- Barometric Pressure Changes: Rapid changes in atmospheric pressure can impact the temperature and pressure within the tanks.

What is Multi-Layer Insulation (MLI)?

Multi-layer insulation (MLI) is a high-performance insulating technique widely used in cryogenic and space applications to prevent heat transmission. It consists of many thin, reflecting materials carefully organized to minimize heat transfer by radiation. This sort of insulation is very useful in areas requiring extremely low temperatures, such as cryogenic storage tanks, liquid gas containers, and spaceships.

Proactive Measures to Mitigate BOG

Our company is dedicated to helping you minimize the risk of BOG in your cryogenic storage tanks. We assist in calculating the appropriate level of insulation needed to achieve your desired boil-off rate goals. Our solutions include various types of insulation materials tailored to your specific needs.

Insulation Solutions Explained

Multi-Layer Insulation (MLI): MLI is a high-performance insulator that uses multiple radiation-heat transfer barriers to slow down energy flow. According to NASA’s Multilayer Insulation Material Guidelines, MLI designs can range from simple blankets to complex series of sub-blankets tailored to fit intricate geometries.

- Thermal Conductivity: Extremely low, ideal for minimizing heat transfer.

- Applications: Suitable for liquid nitrogen, oxygen, and various cryogenic storage systems.

Advantages: Lightweight, flexible, and highly effective in reducing thermal radiation

Application Multi-Layer Insulation (MLI) is commonly used in liquid oxygen tanks and spacecraft to prevent heat absorption during storage and transportation.

Perlite Insulation: Perlite is a natural mineral with a foam-like internal structure, making it an excellent low-density insulator. Due to its unique properties, it is widely used in cryogenic storage tanks and LNG pressure vessels.

- Thermal Conductivity: Low, providing effective insulation.

- Sustainability: Perlite ore is abundant, making it a sustainable choice.

- Applications: Ideal for liquid nitrogen, oxygen, and other cryogenic fluids.

- Advantages: Cost-effective, easy to handle, and provides excellent insulation.

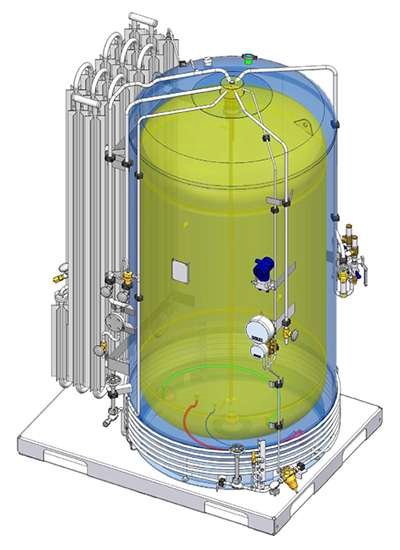

Vacuum Insulation: Vacuum insulation involves creating a vacuum between two layers of the tank wall, effectively eliminating convective and conductive heat transfer. This type of insulation is often used in conjunction with other materials like MLI to enhance performance.

- Thermal Conductivity: Extremely low due to the vacuum layer.

- Applications: Suitable for highly efficient cryogenic storage systems.

- Advantages: Maximizes insulation efficiency and reduces BOG.

Foam Insulation: Polyurethane or polyisocyanurate foams often provide effective thermal insulation.

- Thermal Conductivity: Moderate and effective for a variety of cryogenic applications. Each material has unique thermal conductivity properties, with MLI offering extremely low thermal conductivity, while foam insulation provides moderate levels suited for less critical applications.

- Applications: Suitable for transportation and storage tanks.

- Advantages: Versatile and easy to apply.

Glass Fiber Insulation: Made from fine fibres of glass, this type of insulation provides good thermal resistance.

- Thermal Conductivity: Moderate, effective for both industrial and commercial applications.

- Applications: Used in cryogenic storage systems where moderate insulation is sufficient.

- Advantages: Cost-effective and widely available.

Aerogel Insulation: Aerogel is a highly porous and low-density material with excellent insulating properties.

- Thermal Conductivity: Extremely low, providing maximum insulation.

- Applications: Used in high-performance applications where insulation efficiency is critical.

- Advantages: Superior insulation properties, though relatively expensive.

Composite Insulation Systems: Combining various insulation materials leverages their strengths and minimizes weaknesses.

- Thermal Conductivity: Customizable based on the combination of materials used.

- Applications: Custom-designed for specific cryogenic storage needs.

- Advantages: Superior performance tailored to specific requirements.

Effective management of heat and pressure is essential in preventing BOG in cryogenic storage. By utilizing advanced insulation solutions like MLI, Perlite, Vacuum Insulation, Foam Insulation, Glass Fiber Insulation, Aerogel Insulation, and Composite Insulation Systems, you can significantly reduce the risk of temperature rise and pressure increase. Our expertise and tailored solutions ensure that your cryogenic systems remain efficient, safe, and reliable.

No comment