Liquid nitrogen (LN₂) is a cryogenic, refrigerated liquefied gas widely used across industry, medicine, food processing, and scientific research. Owing to its extremely low boiling point and chemically inert nature, LN₂ plays a critical role in applications requiring rapid cooling, oxygen displacement, or ultra-low-temperature storage.

This article explains how liquid nitrogen is produced, its key physical and chemical properties, safe storage and handling principles, and its most common industrial and commercial applications.

How Liquid Nitrogen Is Produced

Liquid nitrogen is produced in air separation units (ASUs) using cryogenic air separation technology.

The process involves:

-

Air Compression and Purification

Atmospheric air is compressed and filtered to remove dust, moisture, and carbon dioxide, which would otherwise freeze at cryogenic temperatures. -

Cryogenic Cooling and Liquefaction

The purified air is cooled to extremely low temperatures using cryogenic refrigeration systems until it becomes a liquid. -

Fractional Distillation

The liquefied air is passed through a distillation column, where nitrogen, oxygen, and argon are separated according to their different boiling points. Nitrogen, with the lowest boiling point (−196°C), is collected as liquid nitrogen.

This mature and well-controlled industrial process enables the production of high-purity nitrogen suitable for demanding applications.

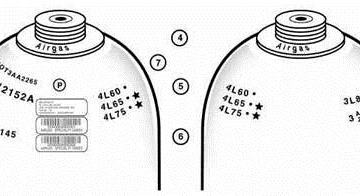

Storage and Distribution of Liquid Nitrogen

Due to its extremely low temperature, liquid nitrogen must be stored and transported in vacuum-insulated cryogenic vessels to minimise heat transfer.

In large-volume applications, LN₂ is typically:

- Transported by cryogenic road tankers

- Stored on site in bulk tanks or MicroBulk vessels

- Drawn off as either liquid or gas, depending on process requirements

Proper insulation allows liquid nitrogen to be stored for extended periods with minimal evaporation losses while ensuring a stable and continuous supply.

Key Physical and Chemical Properties

Liquid nitrogen exhibits several important characteristics that define its industrial usefulness:

- Cryogenic Refrigerated Liquid

Nitrogen gas is liquefied and maintained at cryogenic temperatures to remain in liquid form. - Extremely Low Boiling Point (−196°C)

LN₂ vaporises rapidly at ambient temperatures, enabling fast cooling and freezing. - Colourless, Odourless, and Non-Toxic

Liquid nitrogen is not poisonous; however, it can displace oxygen and pose asphyxiation risks in confined spaces. - Nitrogen Gas Is Heavier Than Air

Vaporised nitrogen may accumulate in low-lying areas, making ventilation and oxygen monitoring essential. - Chemically Inert at Ambient Conditions

Nitrogen does not readily react with most materials, making it suitable for inert atmospheres and protective environments.

Typical Nitrogen Purity Specification

- Nitrogen (N₂): ≥ 99.999%

- Oxygen (O₂): < 5 vpm

- Moisture (H₂O): < 2 vpm

- Argon: Trace amounts naturally present

Exact purity levels depend on production method and intended application.

Industrial and Commercial Applications

Liquid nitrogen is widely used wherever low temperatures, inert environments, or oxygen control are required.

Food and Beverage Industry

- Rapid freezing to preserve food quality and texture

- Modified atmosphere packaging (MAP) to extend shelf life

- Oxygen removal in brewing, soft drinks, and wine production

Medical and Life Sciences

- Long-term cryogenic storage of biological samples

- Preservation of blood, plasma, stem cells, and semen

- Cryosurgical treatment of abnormal tissues

Manufacturing and Engineering

- Heat treatment under protective nitrogen atmospheres

- Cryogenic shrink-fitting of mechanical components

- Pipe freezing for temporary maintenance or modification

- Purging of vessels and pipelines to remove hazardous gases

Electronics and High-Tech Industries

- Inerting of reflow and wave soldering processes

- Reduction of oxidation during PCB manufacturing

Metals and Glass Processing

- Degassing and stirring in steel and aluminium production

- Float glass manufacturing using controlled nitrogen atmospheres

Freeze-Drying and Cryogenic Processing

In freeze-drying (lyophilisation), liquid nitrogen is used to rapidly freeze materials before moisture is removed under vacuum through sublimation. This process is essential for preserving pharmaceuticals, food ingredients, and sensitive biological materials while maintaining structural integrity.

Safety Considerations When Using Liquid Nitrogen

Although non-toxic, liquid nitrogen presents cryogenic and asphyxiation hazards:

- Risk of severe cold burns from direct contact

- Oxygen displacement in confined or poorly ventilated spaces

- Rapid expansion during vaporisation (1 litre of LN₂ expands to ~694 litres of gas)

Safe handling requires proper training, ventilation, oxygen monitoring, and approved cryogenic equipment.

Liquid Nitrogen Supply Models (Overview)

Liquid nitrogen may be supplied in various formats depending on usage volume:

- Portable liquid cylinders

- Refillable Dewar flasks

- MicroBulk cryogenic systems

- Large on-site bulk storage tanks

Each model offers different advantages in terms of capacity, efficiency, and operational flexibility.

Conclusion

Liquid nitrogen is an essential industrial gas with a wide range of applications driven by its ultra-low temperature, inert behaviour, and reliability. Understanding its production, properties, storage methods, and safety requirements is crucial for industries that depend on controlled environments and cryogenic performance.

No comment