Gas Tank Technology

1. The design of DSW gas tank not only uses the specified calculation formula, but also uses the finite element analysis. Then, the calculated data are verified and validated by experiments using various techniques including strain gauge measurement.

2.After analysing chemical, physical, mechanical properties and, if necessary, stress corrosion resistance; all materials (carbon steel,stainless steel, alloy and fiber etc.) are

carefully selected according to the final using conditions.

3.DSW also conducts fracture mechanics analysis on material, which enables us to define the maximum allowable defect size in the cylinder, so that we can:

· determine the NDT limits to be applied to the production line

· guarantee the fatigue life of the cylinder

· demonstrate that the leak occurred before the assumed cylinder burst.

4.The surface protection of gas cylinder is considered as a function of various environmental conditions and various corrosive substance that the cylinder may contact with.

1, ISO standard high quality steel pipe

2.Good quality steel pipe test

3, Production line

4, Shrink cylinder bottom

5, Shrink cylinder mouth

6, Heat treatment

7, Normalizing treatment

8,Assemble cylinder neck

9 Automatic cylinder internal polish

10, Cylinder internal polish checking

11, Automatic spraying prodution line

12, Big cylinder, automatic spraying

13, screw valve

14,leakage test

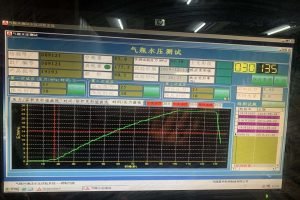

15,Hydraulic Test

16, Permanet expasion test

17, Tensile strength test

18,Yield pressure test

19,bursting test

20, Facory corner

Gas Tank Inspection Guarantee

At DSW, every gas tank undergoes a comprehensive inspection program to ensure maximum safety, reliability, and long-term performance. Our certified processes meet global standards, including ASME, CE/PED, and ISO.

1. Welding & Structural Integrity Testing

- 100% radiographic (RT) and penetrant testing (PT) of all critical weld seams.

- Strength testing using 99.999% high-purity nitrogen to verify structural integrity.

2. Leak Detection & Gas Tightness Verification

- Helium mass spectrometer leak detection with sensitivity up to 2×10-9 Pa·L/s.

- Full gas-tightness and pressure performance tests on inner cylinders and assemblies.

3. Cleanliness, Passivation & Contaminant Control

- Full pickling passivation of inner containers to meet dangerous-goods cleanliness standards.

- UV black-light inspection ensures no oil stains or organic residues.

4. Precision Assembly & Surface Treatment

- Inner and outer tanks assembled within 2.5 hours for efficiency.

- Exterior sandblasting to Sa 2.5 standard; surface dust removed to maintain vacuum integrity.

5. Insulation & Vacuum Integrity

- Interlayer filled with high-quality perlite treated with DSW’s proprietary process.

- Vacuum chamber maintained to strict tolerances to ensure long-term insulation reliability.

6. Final Purging, Sealing & Nitrogen Protection

- All pipelines purged thoroughly with high-purity nitrogen to meet oxygen-use standards.

- Tanks sealed and filled with 0.2 MPa nitrogen for safe protection during transport.

This rigorous inspection process ensures every DSW tank meets international safety standards, delivering dependable performance in demanding industrial applications. Contact DSW for certified gas tank solutions today.